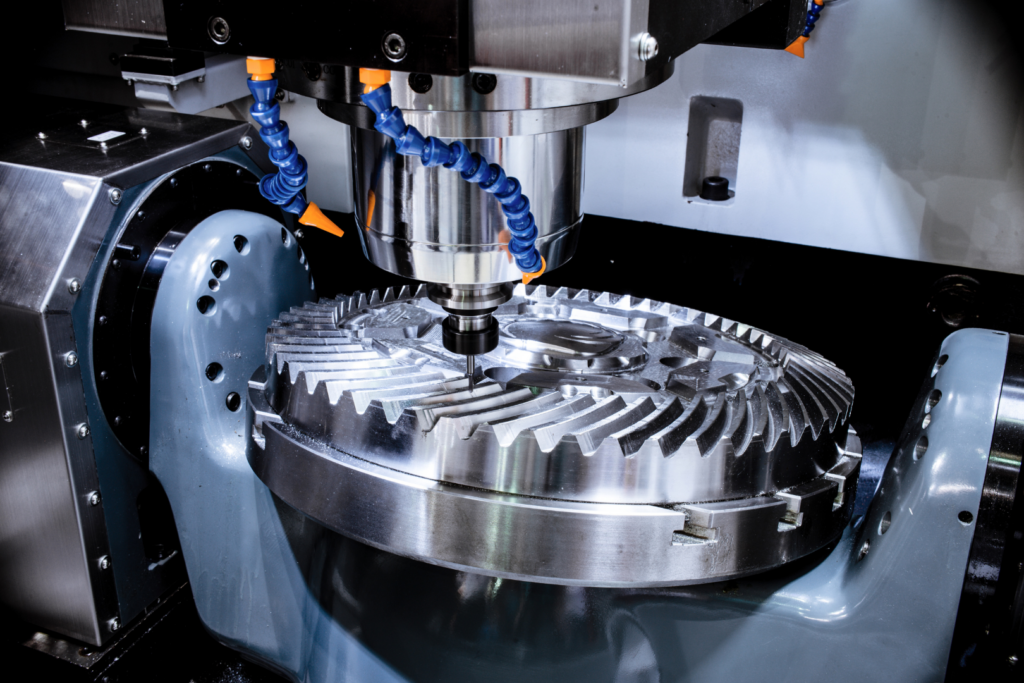

CNC (Computer Numerical Control) machining is a highly automated process that uses computer-controlled machines to cut, mill, drill, or shape materials into precise parts. CNC machines can work with a variety of materials such as metal, plastic, and composites. The process offers exceptional precision, consistency, and speed, making it ideal for creating custom parts that meet the strictest quality standards.

At Rowken Solutions, we provide CNC Machining Services to create highly precise, custom parts for industries ranging from aerospace to automotive, medical, and manufacturing. Using advanced CNC machines, we produce components that meet exact specifications with tight tolerances. Whether you need prototypes, one-off custom parts, or large production runs, our team has the experience and equipment to deliver top-quality results every time.

We pride ourselves on offering a comprehensive suite of CNC machining services that cater to the needs of various industries. Some of the key machining processes we offer include:

At Rowken Solutions, we machine a wide variety of materials to suit your specific application needs, including:

Material | Applications |

Aluminum | Aerospace, automotive, industrial, and lightweight parts |

Stainless Steel | Food processing, medical devices, automotive, industrial applications |

Mild Steel | General manufacturing, automotive, and structural components |

Titanium | Aerospace, medical implants, and high-performance applications |

Brass | Electrical components, plumbing fittings, and decorative parts |

Plastic & Composites | Prototypes, custom enclosures, and lightweight components |

Copper | Electrical components, electronics, and conductive parts |

Our CNC machining services are ideal for producing a wide range of parts and components across various industries. Some of the products we produce include:

Our advanced CNC machines deliver parts with micrometer-level precision and tight tolerances, ensuring high-quality results every time.

We use the latest CNC equipment, ensuring that we can meet even the most challenging project requirements.

We offer competitive pricing for both small and large-scale production runs, with reduced material waste and efficient machining processes.

Whether you need a single prototype or a large production run, we tailor our services to meet your specific requirements.

Ready to bring your design to life with precision CNC machining? Contact Rowken Solutions today for a quote or to discuss your specific project needs. Our team is dedicated to providing the highest quality, efficiency, and customer service for all your CNC machining requirements.